In each enterprise there are always some issues and concerns that cannot be prevented. Nonetheless, because of the advanced know-how and the way in which the business is conducted, there are many problems that can be solved by simple alterations in the electrical design or function of the business'

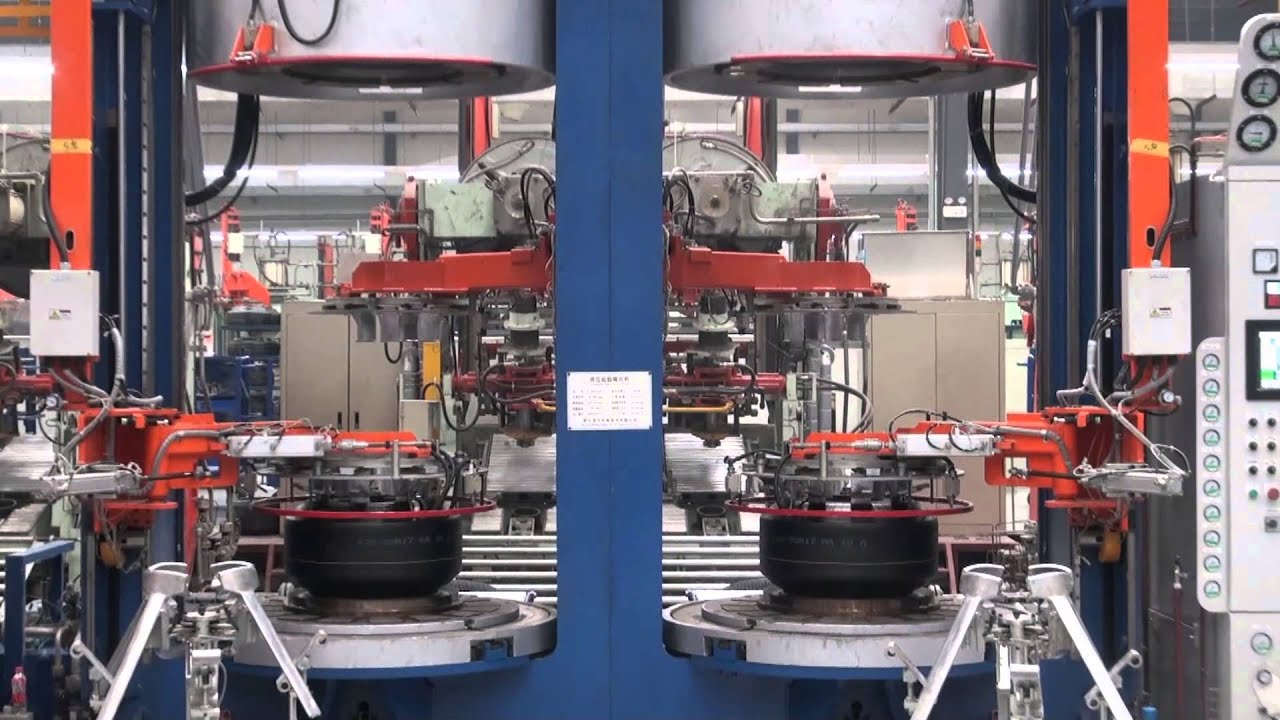

Electronics Manufacturing Tools .

Certainly one of the problems is defective goods.

Electronics Manufacturing Equipment Tips For Newbies depend on their businesses' distribution network to handle all orders for their merchandise. Nonetheless, this system doesn't catch all defective goods and it is mostly attributed to the truth that the distribution network has little to no worker supervision.

The time of receiving info from the manufacturing facility regarding any defective goods can take up to two weeks, which in flip leads to longer time for manufacturers to resolve the issue and place the order for a new product. It's because of this that manufacturers should embody an "motion" system with their manufacturing techniques.

Distributors will not be given any alternate options for the defective items they've with them. When

How Electronics ManufacturingEquipment Can Make Your Business Or Organization Extra Aggressive is confronted with such a situation, then it's good for the distributors to call the manufacturers immediately to fix the issue.

The manufacturers, however, can instantly resolve the potential customer complaints by offering a service called "service standing." This service status will give the distributor sufficient info to determine whether or not the manufacturing equipment continues to be functional or not.

The service standing is a device that the distributor can use to make sure that every one defective goods are fixed by the manufacturer. The distributor can even entry the contact information of the manufacturing tools and if needed can go to the manufacturing facility to guantee that all the pieces is working properly.

Of course, all electronic techniques must be subject to a normal upkeep test at the least as soon as a 12 months. If there are any defects, they are often quickly rectified and may give the distributor a clear image of the efficiency of the enterprise' manufacturing equipment.

It will be important for a distributor to completely understand that in the event that they choose to use a 3rd occasion retailer for their Electronics Manufacturing Gear, there can be additional value. Although many wholesalers offer discounts for retailers, there are numerous wholesalers who will never enable retail purchases to incorporate their brand title.

The wholesaler will only comply with promote to a retailer that has purchased immediately from the manufacturer. They do that because they want to make sure that the retailer has bought the product from the correct individual, which is the producer.

It is also necessary for the distributor to take into consideration the standard price of the electronic units they're purchasing. The prices of such products are normally decided by the manufacturer and they might not change with time.

It's also important for the distributor to purchase the right equipment and to analysis every digital gadgets that they want to sell. They must know what tools they should select and which machine(s) are suitable with one another.

It's important for the distributor to analysis what makes every of the electronic devices the most effective for their prospects.

Electronics Manufacturing Equipment Tips , they must ensure that their purchase goes to fulfill the wants of their prospects earlier than they start promoting.

UNDER MAINTENANCE